Several retrofit areas are planned both in connection with the social housing of Ringgården, administrative building of Ringgården and private single-family houses. The retrofitting demonstration will meet the demands of the low-temperature district heating energy supply to the area, which is also demonstrated in this project.

Retrofitting: The Hasle/Trige area, an area in the north-western part of Aarhus with apartment houses and detached homes) is chosen as the retrofitting area for projects within the Smart Cities call 2013. Moreover, there are private houses in the area that will be addressed. The initiative of this project is the first pilot phase forming the base of a much larger district development in Aarhus, where Denmark’s largest retrofitting project ever is in the planning phase.

During 2014 to 2020, about 400,000 m2 of the area of Gjellerupparken will be totally transformed into a new sustainable retrofitted city district where the READY solutions can be widely replicated. Moreover, the project will benefit from a large new hospital (DNU) which is presently being constructed. The hospital operates cooling and heating. The goal is to reuse all heat from cooling for local district heating within the DNU project. READY will transfer experiences from this project.

In building refurbishment, the demonstration covers:

- BEST – DK1: 23,960 m2 of social housing in Hasle/Skejby – 232 apartments (Ringgården district 21)

- BEST- DK2: 19,464 m2 of social housing in Trige – 181 apartments (Ringgården district 20)

- BEST – DK3: 2,068 m2 of administrative building (Dybedalen 1a)

BEST – DK4: 8,700 m2 private one-family houses approximately 60 in Hasle/Skejby out of a total of 75,000 m2.

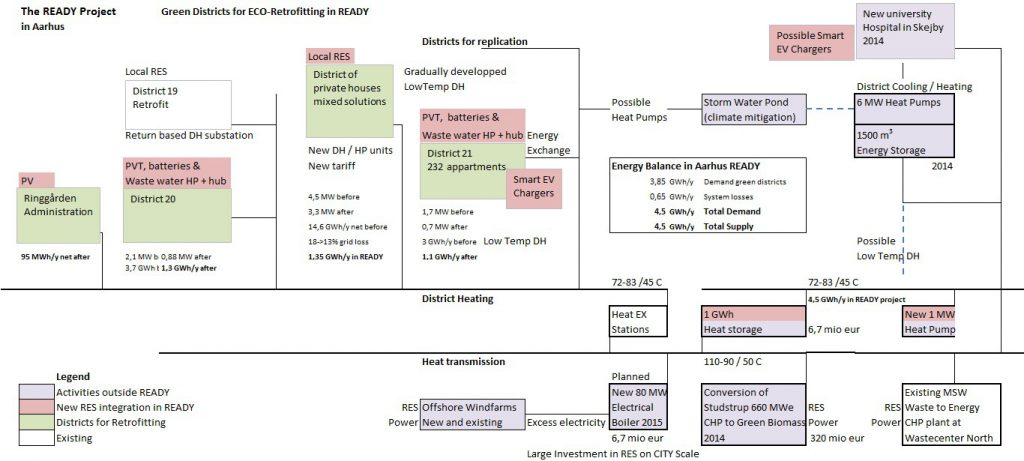

Energy supply system and integration. There are several innovative industrial-driven demonstration projects that all interact in an integrated way within the READY-project area in Aarhus. The overall system is illustrated below:

Aarhus – Electricity and smart grid

Innovative energy recovery from waste water: The heat in the waste water from the buildings will be used for DHW preparation. With prefab installation manholes, a new modular system with buffer, heat pump and smart grid control will be developed for buildings with more 10-40 flats.

Innovative types of low-cost large-size PV-Thermal “PVT” modules from RAC-DK (2050 m2). This project develops and demonstrates new high-efficient PV-T elements in frameless module sizes of 6, 12 and 18 m2. The modules can be used as roofing material and hereby recover heat losses, which will be investigated and demonstrated in the READY area in Aarhus. These modules are not commercially available at this stage – as explained under 1.1.4.6

Innovative technical solutions and business models of battery electric vehicles and the interaction with the low-voltage grid, i.e. intelligent charging. By combining complex ICT systems with innovative charging and battery solutions, Lithium Balance has created a service that in its essence is a flexible energy demand. READY will seek to find another partner/subcontractor who can deliver a battery and integration solution to be demonstrated in Aarhus. These technical and business solutions will be further tested and demonstrated in Aarhus.

Development and testing of (2nd life) battery solutions. With the increasing number of EVs from EV companies like Clever, E.ON, bus companies and private EV users etc. i.e., there will be a need to find ways of resource optimizing the use of batteries which have to be replaced in the cars after some years (around 5) due to their decreased storage and flexibility capacities. In Aarhus, a new concept for battery packs of second-life batteries will be developed and tested in combination with the solar PVT energy and smart grid control solution. The expected life extension is another 8 years at stationary shallow cycling, i.e. a doubling of the total lifespan! before the batteries are sent to material recycling.

Mobilising a virtual power plant. DONG-DK Energy’s Virtual Power Plant (VPP) technology, Power Hub, provides an already operational platform for the READY project with coupling to the energy and ancillary services markets. It is designed for integrating different energy systems, e.g. electricity, gas, district heating/cooling, water and waste/biomass, to optimize the efficiency of each energy system and the combined energy system by matching demand and supply and storage facilities through metering and controls. The Power Hub will be tested for control of individual assets as well as aggregated units, e.g. controlled by a building climate management system.

Integrating district heating and electricity systems. Large-scale (1-5 MW) central heat pumps which will utilise local surplus heat or lake water as heat source will be demonstrated. Focus will be on the potential for synergy between low-temperature heat sources and low-temperature district heating supply. Furthermore, a planned large-scale (80 MW) electric boiler will be evaluated for the possible utilization of fluctuating wind energy and reduce energy overflows in the Aarhus areas. The electric boiler will also serve as a back-up heat source and replace oil-based peak boilers by renewable electricity-based heat. A short-term heat storage (~1000 MWh) is also expected to be installed in order to increase system flexibility. Both projects will be analysed for their potential to lower heat prices.

Efficient resource use: Utilization of food waste from multi-family houses for energy production will be evaluated from an energy, environment and overall resource and consumer point of view. The recommended solution will be implemented and tested in a block of the multi-family buildings in the demonstration area. The relevant scope for scaling will also be identified, not only for Aarhus city but for other cities in the EU as well.

Aarhus – District cooling and heating solutions

Cooling becomes excess heat. The residential area included in the demonstration project is located nearby the new University Hospital (DNU). The hospital will have a local district cooling system installed, based on compressor. Surplus heat from the cooling system will be supplied to the local district heating system through installed heat storage (in order to supply surplus heat at the right time). In this way, energy for cooling and heating is utilized in the most efficient way, and the hospital becomes self-sufficient in heat supply by utilizing waste heat from cooling. Such system has considerable replication potentials both in Aarhus and in other cities.

Low-temperature district heat (LTDH) will be supplied to the dwellings, and new LTDH consumer substations will be installed and demonstrated in single- and multi-family buildings. The temperature of the supplied district heat will be reduced from around (72-83)°C today towards 60°C during summer and 70°C during winter. The reduction of supply temperature will imply reduced heat losses (from around 20% today to around 17%). In multi-family buildings, a new concept of heating and hot water installations will be implemented at apartment level (flat-stations) in selected housing blocks. District heating substations (50 – 300 kW for heating and 50 – 150 kW for domestic hot water with or with-out buffer) for the multi-apartment buildings will be developed and demonstrated during the project.

In order to ensure low-temperature DH supply for all consumers, the few single-family houses which will anyway require higher heating temperatures will be provided with a buffer tank and micro heat pump to boost the temperature of the supplied DH water, enabling of further temperature reduction of the whole district.

Smart metering in district heating. Smart meters will be installed in each dwelling. In the Smart City project, the increased knowledge of user behaviour through the huge amount of consumer data (high time resolution) will be used for forecasting of DH consumption and software-based modelling/analysis in order to optimize the district heating network operation and improve performance. Smart meters will be used to exploit existing distribution networks more efficiently rather than having to invest in additional capacity. Improved operation optimisation will enable lower temperatures in district heating distribution networks. Finally, the collected data will be used at a software platform providing the consumer with information regarding their consumption, settlements, and advices for specific energy efficiency initiatives by including parameters such as flow, return temperature and cooling in the billing.

Aarhus – Mobility and transportation

Aarhus has already worked heavily on coping with the CO2 emission from transport. Cyclist policies and initiatives and light rail are planned, and a large mobility project with the industries in Skejby is ongoing (including currently 8,200 employees growing to 15,000 with the new hospital). The READY project will work upon the results already obtained and intensify the introduction and roll out concepts of electrical vehicles as part of the solutions provided by E.ON. READY has chosen to focus on the commuting aspect, as the main transport challenge of the Skejby community is the heavy commuting caused by the growing number of nearby companies, businesses and the coming extension of the hospital:

- Further measures on reduction of private car commuting and internal transportation in Skejby industrial area – introduction of awareness and benefit measure, public transportation improvements, etc. including monitoring of results.

- Testing of innovative EV deployment plans for Skejby area, campaigns towards industries and businesses in the Skejby area and establishment of charging stations in demonstration settlements and at the DNU (The New University Hospital) in Skejby.

- Demonstration of vehicle sharing and vehicle pooling service integrated with public transportation, company commuting, residential areas etc.